Navigating the CBD Vaporization Landscape: The Rise of Advanced Disposable Solutions

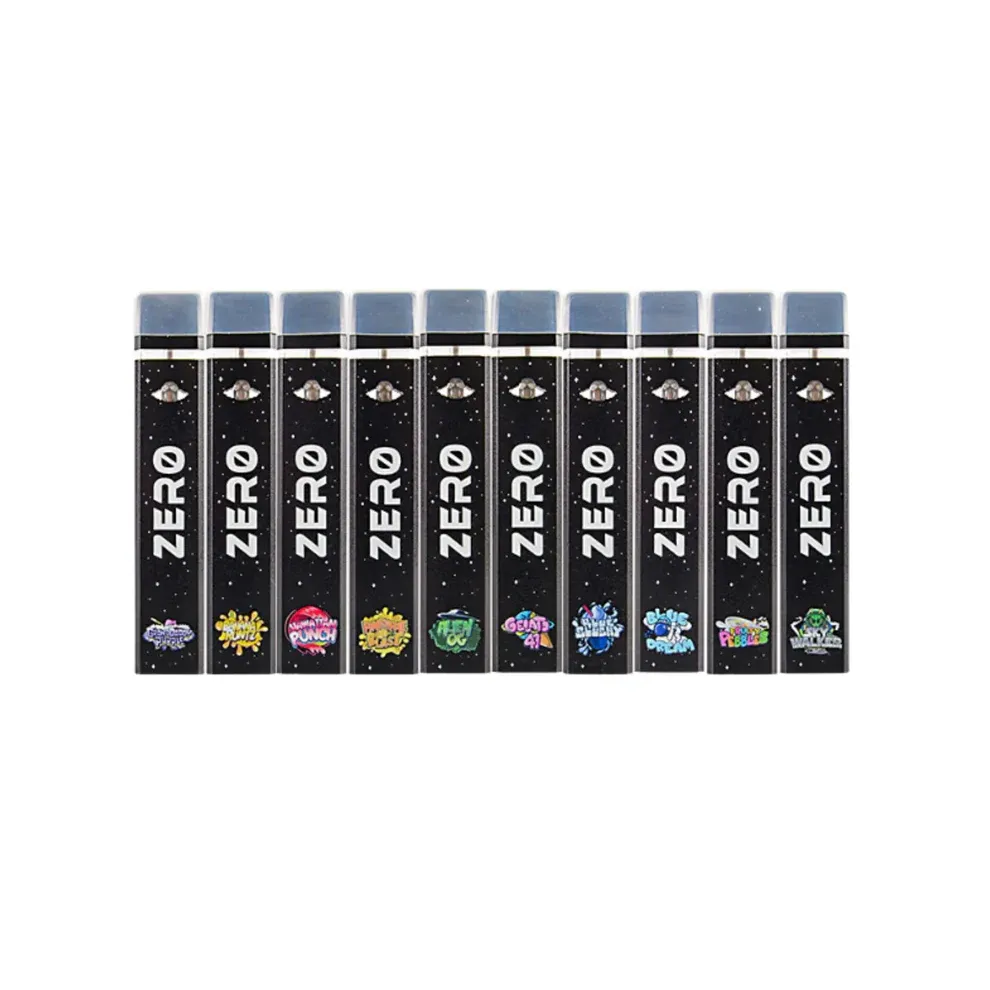

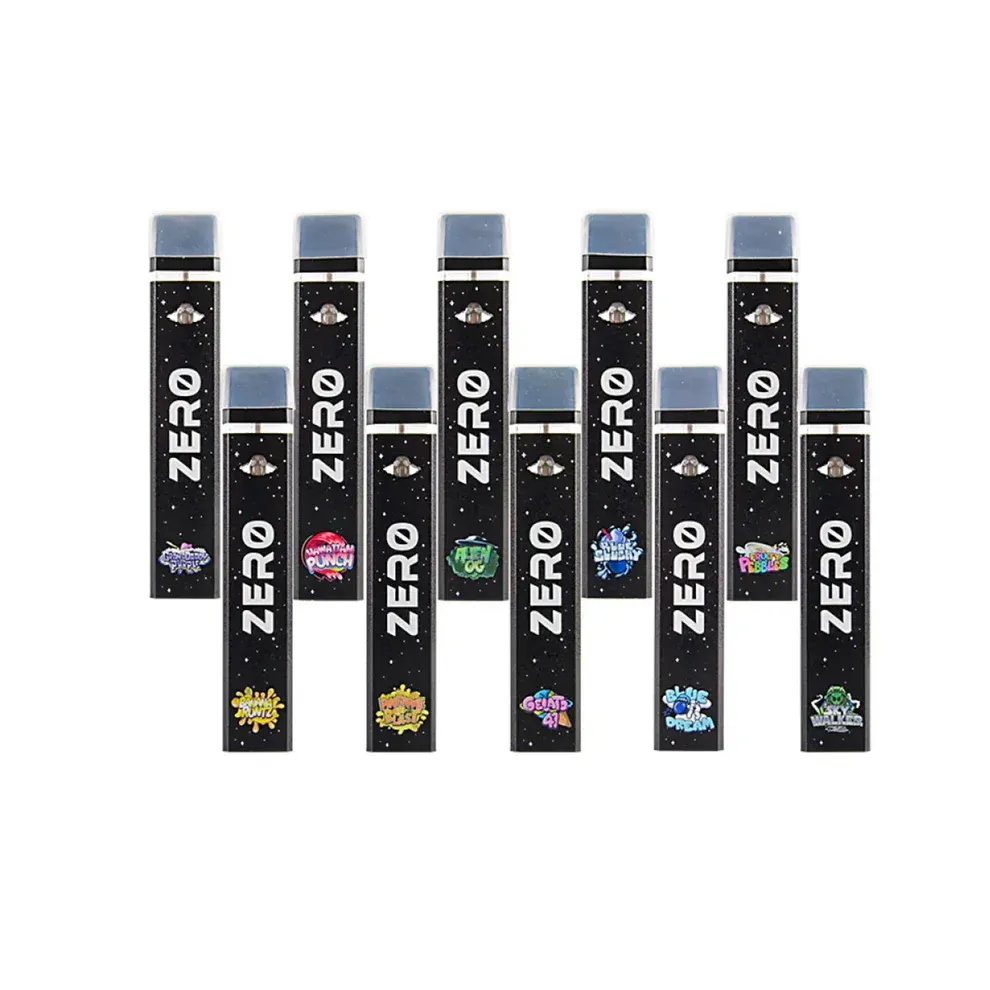

The global CBD market continues its exponential growth, driven by increasing consumer awareness and expanding regulatory frameworks. Within this dynamic ecosystem, the demand for sophisticated, reliable, and user-friendly delivery systems is paramount. Disposable vape solutions have emerged as a dominant trend, offering unparalleled convenience and accessibility. For manufacturers and brand owners, sourcing high-quality empty carts that ensure product integrity and user satisfaction is critical. This article delves into the technical intricacies, market relevance, and manufacturing excellence behind premium solutions like Zero Gravity Disposables Cbd Vape -Empty Carts, designed to meet the rigorous demands of the modern CBD industry.

The market's shift towards disposables is primarily fueled by consumer preference for grab-and-go convenience, coupled with technological advancements that enhance performance and reliability. Industry reports indicate a significant year-over-year increase in the disposable vape segment, with projections showing sustained growth as brands seek to optimize user experience and reduce barriers to entry for new consumers. This trend mandates that the underlying hardware, specifically the empty cartridges, must be engineered for superior oil compatibility, consistent vapor production, and stringent safety standards. Brands prioritizing these factors gain a competitive edge in a crowded marketplace, fostering greater customer loyalty and market share.

The Manufacturing Precision of Zero Gravity Disposables Cbd Vape -Empty Carts

The production of high-performance empty CBD vape carts like the Zero Gravity Disposables Cbd Vape -Empty Carts is a complex, multi-stage process demanding meticulous attention to detail, advanced engineering, and rigorous quality control. This process ensures the finished product reliably preserves CBD oil integrity, prevents leakage, and delivers a consistent, enjoyable user experience.

Materials Selection and Sourcing

- Heating Element: High-purity ceramic coils are fundamental. These are chosen for their inertness, excellent thermal stability, and ability to atomize viscous CBD oils efficiently without burning, preserving cannabinoid and terpene profiles. Materials are often sourced from certified suppliers to ensure heavy metal-free compliance (e.g., RoHS, CE standards).

- Reservoir: Medical-grade PCTG (Polycyclohexylenedimethylene Terephthalate Glycol) or borosilicate glass are preferred. PCTG offers superior chemical resistance, durability, and clarity compared to traditional plastics, making it ideal for maintaining the purity and visual appeal of CBD oil. Glass provides maximum inertness.

- Housing and Internal Components: Food-grade stainless steel (e.g., SUS316L) is used for critical internal components that contact the oil or vapor path, ensuring corrosion resistance and minimizing leaching. Sealing components are typically medical-grade silicone or specialized O-rings designed for high-temperature and chemical exposure.

- Mouthpiece: Options include food-grade PCTG, ceramic, or metal, designed for ergonomic comfort and to withstand user contact without degradation.

Manufacturing Process Flow (Schematic Steps)

The production typically follows a highly automated and controlled sequence:

Step 1: Component Fabrication & Precision Machining

- Ceramic Coil Sintering: High-purity ceramic powder is pressed and sintered at extreme temperatures to form porous heating elements.

- CNC Machining: Metal components (e.g., base connectors, internal rods) are precision-machined from stainless steel using Computer Numerical Control (CNC) technology, ensuring exact tolerances and smooth finishes for optimal sealing and airflow.

- Injection Molding: PCTG reservoirs and mouthpieces are produced via high-precision injection molding, ensuring consistent dimensions and flawless surfaces.

Step 2: Component Cleaning & Sterilization

- All components undergo multi-stage ultrasonic cleaning using medical-grade solvents, followed by rinsing with deionized water and drying in Class 1000 cleanroom environments to eliminate contaminants.

- Sterilization processes (e.g., UV-C irradiation) are applied to critical components to meet hygienic standards.

Step 3: Automated Assembly in Cleanroom

- Assembled using high-precision robotic systems within ISO Class 8 (or better) cleanrooms to prevent particulate contamination.

- Ceramic coils are integrated with their wicking systems and connected to the electrical contacts.

- Reservoir, heating element, base, and mouthpiece are securely joined, often using pressure-fit or low-temperature welding techniques to avoid adhesive contamination.

Step 4: Comprehensive Quality Control & Testing

- Airflow Resistance Test: Each unit is checked for consistent draw resistance.

- Leakage Test: Advanced vacuum and pressure tests simulate real-world conditions to detect any potential leaks.

- Heavy Metal Analysis: Random batch testing using ICP-MS (Inductively Coupled Plasma – Mass Spectrometry) ensures compliance with strict heavy metal limits (e.g., California’s Cat III heavy metal limits).

- Material Purity Verification: FTIR (Fourier-Transform Infrared Spectroscopy) may be used to verify material composition.

- Dimensional Accuracy: Optical inspection systems verify all critical dimensions against CAD specifications.

Step 5: Packaging

- Finished, inspected units are packaged in protective, often sterile, packaging to maintain integrity during transit and storage.

Testing Standards and Target Industries

Manufacturing adheres to international standards such as ISO 9001 for quality management systems and often ISO 13485 for medical device quality, reflecting the stringent requirements for consumer safety. Materials often comply with FDA food-contact standards (e.g., 21 CFR 177.1580 for PCTG) and RoHS (Restriction of Hazardous Substances) directives.

Target industries include CBD product manufacturers, cannabis extractors, pharmaceutical companies developing cannabinoid-based therapies, and wellness brands. Advantages in typical application scenarios include:

- Consistent Dosing: Precision-engineered airflow and coil technology ensure uniform vapor production, crucial for accurate CBD delivery.

- Corrosion Resistance: Use of medical-grade stainless steel and inert ceramic/PCTG materials prevents degradation from various CBD oil formulations, extending service life and maintaining product purity.

- Leak Prevention: Advanced sealing mechanisms and tight manufacturing tolerances drastically reduce the risk of costly and messy leaks, a common pain point in lower-quality alternatives.

- Enhanced Flavor Profile: Ceramic coils operate at optimal temperatures, preserving the delicate terpene profiles of CBD extracts, leading to a superior user experience.

Technical Specifications and Performance Parameters

Understanding the core technical specifications of Zero Gravity Disposables Cbd Vape -Empty Carts is crucial for B2B decision-makers. These parameters directly influence product performance, consumer safety, and overall brand reputation.

Key Product Specifications Table

| Parameter | Specification | Technical Advantage |

|---|---|---|

| Capacity Options | 0.5mL, 1.0mL | Versatility for different product sizes and market segments. |

| Heating Element | Advanced Ceramic Coil (Porous Structure) | Consistent heating, efficient atomization of high-viscosity oils, pure flavor, heavy metal-free. |

| Coil Resistance | Typically 1.2 – 1.6 Ohms | Optimized for standard 510-thread batteries, balanced vapor production and battery life. |

| Oil Intake Holes | 2.0mm - 2.5mm (adjustable) | Accommodates various CBD oil viscosities, ensuring efficient wicking and preventing dry hits. |

| Materials (Oil Path) | Medical-grade PCTG or Borosilicate Glass, Ceramic, Food-grade SUS316L Stainless Steel | Chemical inertness, heavy metal-free assurance, high durability, excellent heat resistance. |

| Leakage Rate | < 0.1% (Post-factory testing) | Minimizes product loss and customer dissatisfaction; industry-leading leak prevention. |

| Heavy Metal Compliance | RoHS, CE, California Cat III (and beyond) | Ensures consumer safety and regulatory adherence in key global markets. |

| Fill Method | Top Fill (with Press-on Mouthpiece) | Facilitates efficient, automated filling for manufacturers, tamper-evident sealing. |

| Service Life (Empty Cart) | Up to 2 years (unfilled, stored correctly) | Ensures longevity for inventory management and flexibility in production schedules. |

These specifications are not merely numbers; they represent the culmination of advanced material science and engineering. For instance, the low leakage rate is a direct result of precision CNC machining of metal components and the careful selection of medical-grade sealants, significantly reducing product waste and enhancing consumer trust. The porous ceramic heating element optimizes surface area for oil absorption and vaporization, leading to superior flavor rendition and vapor density, even with highly viscous full-spectrum CBD oils.

Technical Advantages and Application Scenarios

The inherent advantages of Zero Gravity Disposables Cbd Vape -Empty Carts extend beyond mere specifications, translating into tangible benefits for both B2B clients and their end-users. These advantages are crucial differentiators in a competitive market.

Core Technical Advantages

- Optimized Viscosity Compatibility: Engineered with varied intake hole sizes and a highly absorbent ceramic coil, these carts flawlessly handle a wide range of CBD oil viscosities, from thin distillates to thicker live resin extracts, ensuring consistent wicking without clogging.

- Purity and Flavor Preservation: The inert material construction (ceramic, glass, medical-grade stainless steel) eliminates interaction with the CBD oil, preventing metallic tastes or chemical leaching. This preserves the delicate terpene profiles and the natural flavor of the extract.

- Superior Leak Resistance: Multi-layered sealing mechanisms, including advanced O-rings and precision-fit components, are factory-tested to virtually eliminate leakage, a critical factor for product integrity and consumer satisfaction.

- Robust Construction for Durability: Designed to withstand typical handling and transportation stresses. The chosen materials offer excellent impact resistance, reducing breakage rates.

- Consistent Vapor Output: The optimized coil resistance and airflow system deliver a smooth, consistent draw and vapor volume from the first puff to the last, ensuring a uniform user experience.

- Heavy Metal-Free Assurance: Strict material sourcing and manufacturing processes guarantee compliance with the most stringent heavy metal testing requirements, providing a safe product for consumers.

Application Scenarios

- CBD Brand Manufacturing: Ideal for white-labeling and branded CBD vape products, allowing brands to fill with their unique formulations (full-spectrum, broad-spectrum, isolates) and achieve a premium end-product.

- Medical Cannabis Market: Suitable for medical dispensaries and licensed producers requiring reliable, consistent, and safe delivery systems for therapeutic cannabis extracts. The empty carts enable precise dosage control and maintain medicinal integrity.

- Wellness and Nutraceutical Companies: For companies incorporating CBD into wellness products, these disposables offer a convenient and effective method for consumers to integrate CBD into their daily routines.

- Research and Development: Their consistent performance makes them excellent tools for R&D in cannabinoid sciences, allowing researchers to accurately test different formulations and extract types.

Vendor Comparison and Customized Solutions

In a crowded market of vape hardware suppliers, distinguishing between vendors based on objective criteria is essential for making informed procurement decisions. Choosing the right partner for Zero Gravity Disposables Cbd Vape -Empty Carts involves evaluating their commitment to quality, innovation, and client support.

Product Comparison Table: Zero Gravity vs. Standard Empty Carts

| Feature | Zero Gravity Disposables Cbd Vape -Empty Carts | Standard Empty Cartridges (General Market) |

|---|---|---|

| Coil Technology | Advanced Porous Ceramic Core, High Purity | Cotton wicks, older ceramic designs, or basic metal coils |

| Oil Compatibility | Optimized for wide range of viscosities, including highly viscous distillates/live resin | May struggle with thicker oils, prone to clogging or dry hits |

| Material Safety | Medical-grade PCTG/Glass, SUS316L SS, Heavy Metal-Free Certified | Lower-grade plastics, unknown metal alloys, potential heavy metal leaching |

| Leakage Rate | < 0.1% (Rigorous testing) | Often 1-3% or higher, inconsistent sealing |

| Flavor Preservation | Excellent, pure taste profile due to inert materials and optimal heating | Can impart metallic or burnt taste, degrade terpene profiles |

| Manufacturing Environment | ISO Class 8 Cleanroom Assembly, Automated Processes | Standard factory environments, manual assembly, higher contamination risk |

| Certifications | ISO 9001, CE, RoHS, Heavy Metal Test Reports | Often limited or basic certifications |

Customized Solutions for Brand Differentiation

Recognizing the unique branding needs of B2B clients, providers of Zero Gravity Disposables Cbd Vape -Empty Carts often offer extensive customization options:

- Color and Finish: Custom colors for the mouthpiece, base, or entire body, utilizing food-grade coatings that are safe and durable. Options include matte, glossy, metallic, or soft-touch finishes.

- Branding and Logos: Laser engraving, silk-screen printing, or pad printing for brand logos, product names, or compliance information directly onto the device.

- Mouthpiece Design: Bespoke mouthpiece shapes (e.g., flat, round, ergonomic) and materials (e.g., ceramic, wood, specialized plastics) to match brand aesthetics and user preference.

- Capacity Adjustments: While standard capacities are 0.5mL and 1.0mL, specific project requirements for other volumes can sometimes be accommodated for large orders.

- Packaging: Custom packaging solutions, including child-resistant features, display boxes, blister packs, and individual protective sleeves, all designed to enhance brand appeal and meet regulatory requirements.

- Oil Intake Hole Configuration: Fine-tuning the size and number of oil intake holes to precisely match the viscosity profile of a client's specific CBD formulation.

Application Case Studies and Customer Experience

Real-world application demonstrates the tangible benefits and reliability of high-quality vape hardware. These cases highlight how advanced solutions like Zero Gravity Disposables Cbd Vape -Empty Carts contribute to client success and end-user satisfaction.

Case Study 1: Premium CBD Tincture Brand Expansion

A well-established premium CBD tincture brand sought to diversify its product line by introducing a disposable vape option for its high-viscosity, full-spectrum CBD extract. Their previous attempts with standard carts resulted in frequent clogging and an inconsistent user experience, damaging brand reputation. By adopting Zero Gravity Disposables Cbd Vape -Empty Carts, featuring optimized ceramic coils and larger intake holes, the brand successfully launched its new vape line. Customer feedback highlighted the smooth draw, rich flavor, and complete absence of clogs or leaks. This led to a 30% increase in new customer acquisition within the first quarter and solidified their position as an innovator in the premium CBD sector.

Case Study 2: Medical Dispensary Chain Product Standardization

A large medical cannabis dispensary chain operating across multiple states needed a standardized, highly reliable disposable vape solution for its diverse range of medicinal CBD and THC formulations. Consistency in dosing and product safety were paramount. After an exhaustive evaluation process, they selected Zero Gravity Disposables Cbd Vape -Empty Carts due to their stringent heavy metal compliance, low leakage rates, and consistent vapor delivery. Implementing these carts across all product lines streamlined their manufacturing, reduced product returns by 75%, and significantly improved patient trust and satisfaction. The chain reported enhanced operational efficiency and a stronger adherence to pharmaceutical-grade standards.

Customer Feedback & Service Excellence

Ongoing customer feedback consistently praises the reliability and performance of Zero Gravity Disposables Cbd Vape -Empty Carts. Clients frequently report improved product integrity, fewer customer complaints related to hardware malfunctions, and enhanced flavor profiles for their concentrates. This positive reception is backed by a commitment to exceptional service, from initial consultation and sample provision to post-sales technical support. Our dedicated engineering teams work closely with clients to troubleshoot specific oil formulations, ensuring optimal performance from the empty carts.

Ensuring Trustworthiness: FAQs, Fulfillment, Warranty & Support

Frequently Asked Questions (FAQ)

Q: Are these carts suitable for high-viscosity CBD distillates?

A: Yes, Zero Gravity Disposables Cbd Vape -Empty Carts are specifically engineered with advanced ceramic coils and optimized intake holes (2.0-2.5mm) to handle a wide range of oil viscosities, including highly viscous distillates, without clogging or dry hits.

Q: What certifications do your products hold?

A: Our manufacturing facilities are ISO 9001 certified. The products comply with CE, RoHS, and undergo rigorous heavy metal testing to meet or exceed California's Cat III limits and other global safety standards.

Q: Can I customize the appearance of the carts with my brand's logo?

A: Absolutely. We offer comprehensive customization options including laser engraving, silk-screen printing, custom color finishes, and bespoke mouthpiece designs to align with your brand identity.

Q: What is the typical lead time for an order?

A: Standard orders typically have a lead time of 10-15 business days after order confirmation and payment. Customized orders may require an additional 5-7 business days for production and quality checks. Expedited options are available upon request.

Lead Time and Fulfillment Details

Our efficient supply chain and automated manufacturing processes ensure timely fulfillment. For bulk orders of standard Zero Gravity Disposables Cbd Vape -Empty Carts, lead times are typically 10-15 business days. For orders requiring extensive customization, the lead time may extend to 15-25 business days, depending on the complexity of the customization. We work with reputable global logistics partners to ensure secure and expedited delivery to your facility, offering various shipping options to meet your scheduling and budgetary needs. All shipments are carefully packed to prevent damage during transit.

Warranty Commitments

We stand by the quality and performance of our Zero Gravity Disposables Cbd Vape -Empty Carts. A standard 6-month limited warranty is provided from the date of purchase, covering manufacturing defects. This warranty ensures that products are free from defects in materials and workmanship under normal use. Any product found to be defective due to manufacturing error will be replaced or credited. Our commitment to quality control is reflected in an industry-leading low defect rate of less than 0.1%, offering peace of mind to our B2B partners.

Customer Support Information

Our dedicated customer support team is available to assist with any inquiries, from technical specifications and order placement to after-sales support. Clients can reach us via:

- Email: sales@icoolvape.com

- Phone: Available during business hours (specific number provided upon request)

- Online Portal: Secure client portal for order tracking, technical documentation, and support ticket submission.

We are committed to building long-term partnerships through responsive and expert support, ensuring your operations run smoothly and efficiently.

Conclusion

The evolving CBD market demands vape hardware that embodies precision engineering, material purity, and unwavering reliability. Zero Gravity Disposables Cbd Vape -Empty Carts represent the pinnacle of this advancement, offering a superior solution for brands committed to quality and consumer satisfaction. From their meticulously controlled manufacturing process, adherence to rigorous testing standards, and robust technical specifications, these empty carts provide a foundation for exceptional CBD vaping experiences. The comprehensive support structure, including flexible customization, clear fulfillment processes, and a solid warranty, further reinforces their position as a trusted partner for B2B clients globally. Choosing these advanced disposable empty carts ensures not just product delivery, but the delivery of a premium, safe, and consistent brand experience, driving sustained success in the competitive cannabinoid industry.

Authoritative References

- International Organization for Standardization (ISO). ISO 9001:2015 - Quality management systems. Retrieved from iso.org

- International Organization for Standardization (ISO). ISO 13485:2016 - Medical devices - Quality management systems. Retrieved from iso.org

- European Union. Directive 2011/65/EU on the restriction of the use of certain hazardous substances in electrical and electronic equipment (RoHS 2). Retrieved from eur-lex.europa.eu

- U.S. Food and Drug Administration (FDA). Title 21 Code of Federal Regulations, Part 177: Indirect Food Additives: Polymers. Retrieved from accessdata.fda.gov

- California Department of Public Health (CDPH). Cannabis Edible and Inhalable Product Testing Regulations. Retrieved from cdph.ca.gov

- Grand View Research. CBD Market Size, Share & Trends Analysis Report. Retrieved from grandviewresearch.com

Post time:Sep - 02 - 2025